Tin Snips from BESSEY: Quality for precise cuts

Are you looking for reliable sheet metal shears that optimally meet your work requirements? At BESSEY, you will find high-quality sheet tin snips that are characterised by quality and precision. Our sheet metal shears are the perfect choice for professionals and DIY enthusiasts who need precise cuts in various materials.

One of our top recommendations is the D39ASS Shape and straight cutting snips. Thanks to its sintered steel insert, it is particularly smooth-running and cuts through sheet metal up to 1.2 mm thick with ease. For versatile applications in the home and workshop, we recommend the D820 multi-purpose shears with soft inserts in the handle eyes. These shears offer maximum comfort and precision.

BESSEY stands for quality and innovation. Our products are carefully manufactured from high-quality materials to ensure optimum results. The quality of the cutting edges plays a decisive role in the longevity of our tools.

Overview of Standard Tin Snips

1: Straight cutting snips

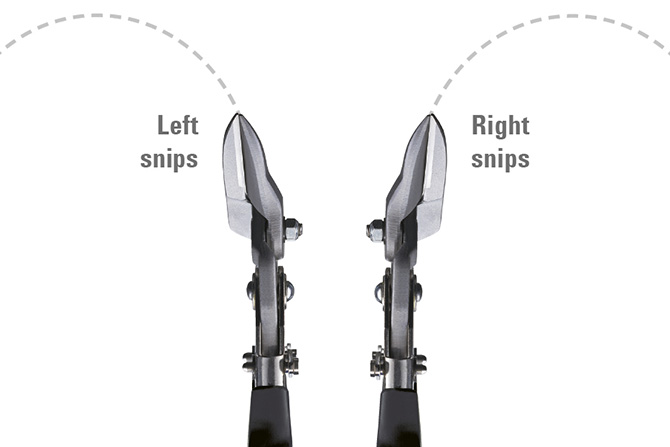

2: Aviation snips

3: Shape and straight cutting snips

Overview of Compound Leverage Snips

4: Compund leverage straight cutting snips

5: Compound leverage aviation snips

6: Compound leverage shape and straight cutting snips