Made for precise cutting: professional tools for metal, sheet metal and more

Sharp. Robust. Developed for professionals who work with precision every day.

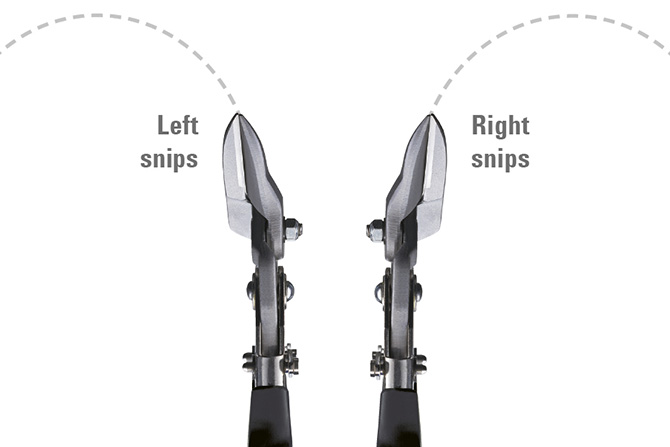

Whether sheet metal, aluminium or fine materials – every cut counts in cutting technology. BESSEY offers you clever solutions for this: from robust sheet metal shears and versatile combination shears to lever-assisted models for maximum force, to precise cutter knives and handy multi-tools. Our tools are designed for tough everyday use in workshops and on construction sites – and make your work easier, faster and more accurate.

When it comes to cutting with millimetre precision and clean cut edges, you can rely on BESSEY. Our cutting tools offer powerful performance with minimal effort – ideal for professionals in metal construction, plumbing or for precise work around the home. They are well thought-out down to the last detail, built to last and perfectly tailored to your requirements. This allows you to work more efficiently, more safely and with genuine professional tools that deliver what they promise.

Further ranges of cutting technology

What users say about our products

"I love BESSEY hand-operated tin snips! Since completing my training, I wouldn't want to cut anything with anything else. They're precise and, above all, comfortable to hold."

Mitsch

Plumber