Diseñadas para un corte preciso: herramientas profesionales para metal, chapa y mucho más

Precisión. Robustez. Diseñadas para profesionales que trabajan a diario con precisión.

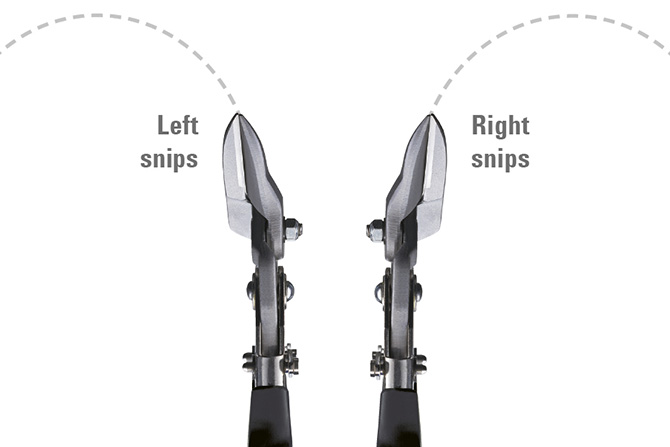

Ya sea chapa, aluminio o materiales delicados, en la técnica de corte cada corte cuenta. BESSEY le ofrece soluciones inteligentes para ello: desde robustas tijeras para chapa y versátiles tijeras combinadas, pasando por modelos con palanca para obtener la máxima fuerza, hasta precisas cuchillas de corte y prácticas herramientas multiusos. Nuestras herramientas están diseñadas para el duro trabajo diario en el taller y la obra, y hacen que su trabajo sea más fácil, rápido y preciso.

Cuando se trata de obtener resultados milimétricos y bordes de corte limpios, puede confiar en BESSEY. Nuestras herramientas de corte ofrecen un gran rendimiento con un mínimo esfuerzo, lo que las hace ideales para profesionales de la construcción metálica, la fontanería o para trabajos de precisión en el hogar. Están diseñadas hasta el último detalle, son duraderas y se adaptan perfectamente a sus necesidades. De este modo, trabajará de forma más eficiente y segura con herramientas profesionales que cumplen lo que prometen.

Otras gamas de productos de tecnología de corte

Esto es lo que dicen los usuarios sobre nuestros productos

«¡Me encantan las tijeras para chapa manuales de BESSEY! Desde que terminé mi formación, no quiero cortar con ninguna otra herramienta. Son precisas y, sobre todo, muy cómodas de manejar».

Mitsch

Fontanero