정밀 절단을 위한 전문 도구: 금속, 판금 및 기타 재질을 위한 프로페셔널 도구

날카롭다. 견고하다. 매일 정밀하게 작업하는 전문가들을 위해 개발되었습니다.

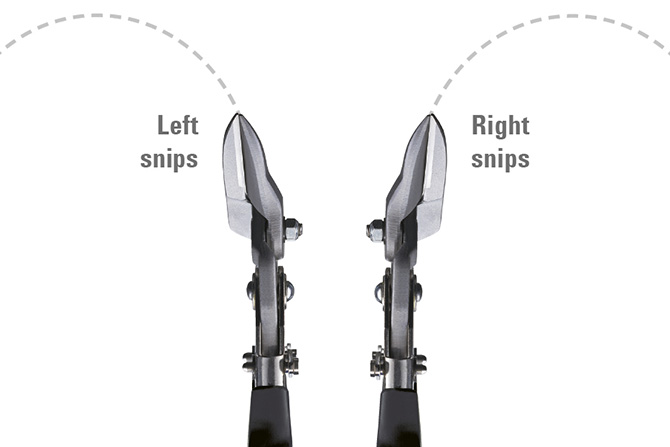

금속판, 알루미늄 또는 정밀 소재 – 절단 기술에서는 모든 절단이 중요합니다. BESSEY는 이를 위한 스마트한 솔루션을 제공합니다: 견고한 금속 가위와 다용도 콤비 가위부터 최대 힘을 위한 레버 변속 모델, 정밀 커터 나이프와 휴대하기 편한 멀티툴까지. 당사의 공구는 가혹한 작업장 및 건설 현장의 일상 작업을 위해 설계되어 작업을 더 쉽고, 빠르고, 정확하게 만들어 줍니다.

밀리미터 단위의 정밀한 절단 결과와 깔끔한 절단면을 원한다면 BESSEY를 믿으세요. 저희 절단 도구는 적은 힘으로도 강력한 성능을 발휘하여 금속 구조물 제작, 배관공 작업 또는 가정 내 정밀 작업에 이상적입니다. 세심한 디테일로 설계되고 내구성이 뛰어나며 사용자의 요구에 완벽하게 부합합니다. 이를 통해 약속한 성능을 발휘하는 진정한 전문 공구로 더 효율적이고 안전하게 작업할 수 있습니다.

절단 기술의 추가 제품군

사용자들이 우리 제품에 대해 말하는 것

„저는 BESSEY의 수동 금속 가위를 사랑합니다! 견습 시절 이후로 다른 도구로는 절단하고 싶지 않아요. 정밀하고 무엇보다도 손에 편안하게 잡힙니다.“

미츠

플라스히너