精密な切断のために作られました:金属、板金など用のプロ用工具

シャープで頑丈。毎日精密な作業を行うプロフェッショナル向けに開発されました。

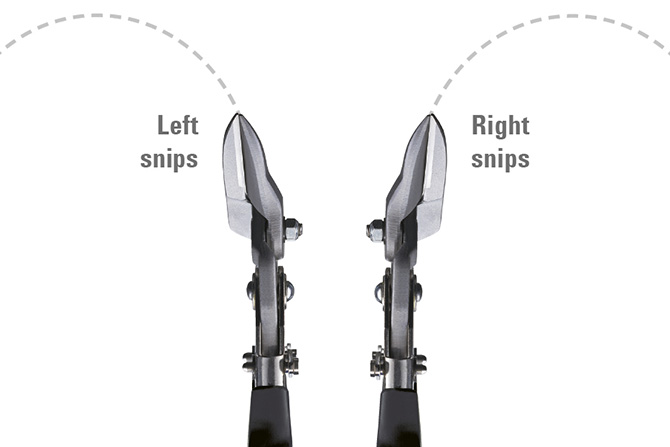

板金、アルミニウム、繊細な素材など、切断技術では、1回の切断がすべてです。BESSEY は、頑丈な板金用はさみや多用途のコンビはさみ、最大の力を発揮するレバー式モデル、精密なカッターナイフ、扱いやすいマルチツールなど、賢いソリューションをご提供いたします。当社の工具は、過酷な作業場や建設現場での日常的な使用に耐えるよう設計されており、お客様の作業をより簡単、より迅速、より正確にします。

ミリ単位の精度ときれいなカットエッジが求められる切断作業には、BESSEY 製品をご信頼ください。当社の切断工具は、少ない力でも強力な性能を発揮します。金属構造、板金加工の専門家や、家庭での精密な作業に最適です。細部に至るまで考え抜かれた、耐久性に優れた構造で、お客様の要件にぴったり合っています。これにより、効率的で安全、そして期待通りの性能を発揮する、真のプロ仕様の工具を使って作業することができます。

その他の切断技術関連製品

ユーザー様の当社製品に関するご感想

「私は BESSEY の手動ブリキはさみが大好きです!研修以来、他の製品では切断作業をしたくありません。正確で、何よりも手に心地よくフィットします。」

ミッチ・

、配管工