Hassas kesim için üretilmiştir: Metal, sac ve daha fazlası için profesyonel aletler

Keskin. Sağlam. Her gün hassas çalışmalar yapan profesyoneller için geliştirilmiştir.

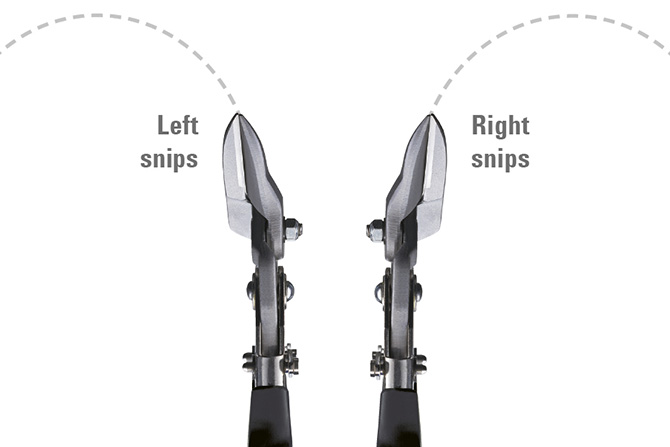

Sac, alüminyum veya ince malzemeler – kesme teknolojisinde her kesim önemlidir. BESSEY size bu konuda akıllı çözümler sunar: sağlam sac makasları ve çok yönlü kombine makaslardan, maksimum güç için kaldıraçlı modellere, hassas kesici bıçaklara ve kullanışlı çok amaçlı aletlere kadar. Aletlerimiz, zorlu atölye ve şantiye koşulları için tasarlanmıştır ve işinizi daha kolay, daha hızlı ve daha hassas hale getirir.

Kesim sırasında milimetrik hassasiyet ve temiz kesim kenarları önemliyse, BESSEY'e güvenebilirsiniz. Kesme aletlerimiz, az güçle yüksek performans sunar – metal yapı, çatı kaplama veya evdeki hassas işler için idealdir. Ayrıntısına kadar düşünülmüş, dayanıklı ve ihtiyaçlarınıza mükemmel şekilde uyarlanmışlardır. Böylece, vaat ettiklerini yerine getiren gerçek profesyonel aletlerle daha verimli, daha güvenli ve daha etkili çalışabilirsiniz.

Kesme teknolojisinin diğer ürün yelpazeleri

Kullanıcılar ürünlerimiz hakkında ne diyor?

"BESSEY'in el sac makaslarını çok seviyorum! Eğitimimden bu yana başka bir şey kullanmak istemiyorum. Hassas ve özellikle de elde tutması çok rahat."

Mitsch

Flaschner